Welcome to our Full-Service Women's Apparel Manufacturing Hub, Specializing in Ready-to-Wear (RTW), Woven, Knit-Related, Denim, and Athleisure Clothing. We proudly operate 6 owned state-of-the-art factories across the globe, in addition to partnering with over 50 cooperative factories worldwide.

New York City Presence.

Our dedicated sales and design teams are based in the heart of New York City - under the umbrella of ESEN International Co., Ltd. in ZhangJiaGang City, Jiangsu Province. All our factories have credited certifications WRAP/BSCI/SEDEX with locations in China, Vietnam, and Egypt - providing you with unparalleled support and inspiration.

Sustainability Matters.

We believe in sustainability and can offer your brand ways to design responsibly - always using the best quality fabrics, producing samples with fast lead times, and offering your design teams endless capabilities.

At Green Win Zone US, sustainability is not just a buzzword; it's our core principle. We are dedicated to helping your brand design responsibly and be "eco-conscious" from concept to completion. We achieve this by sourcing a higher percentage of fabrics that are either organically produced or recycled, ensuring your fashion choices have a positive impact on the planet.

Unleash your creativity with advanced fabric matching and finishing technology deployed by Green Win Zone US to give you the best results.

At Green Win Zone US, we bring innovation to women apparel production, catering to fashion brands, retailers, and bulk orders. Our commitment is to provide an efficient, cost-effective, and sustainable production process that's second to none. We use the latest indstrutry-leading and sustainable technology - using advanced Jeanologia machinery in our denim production wash process.

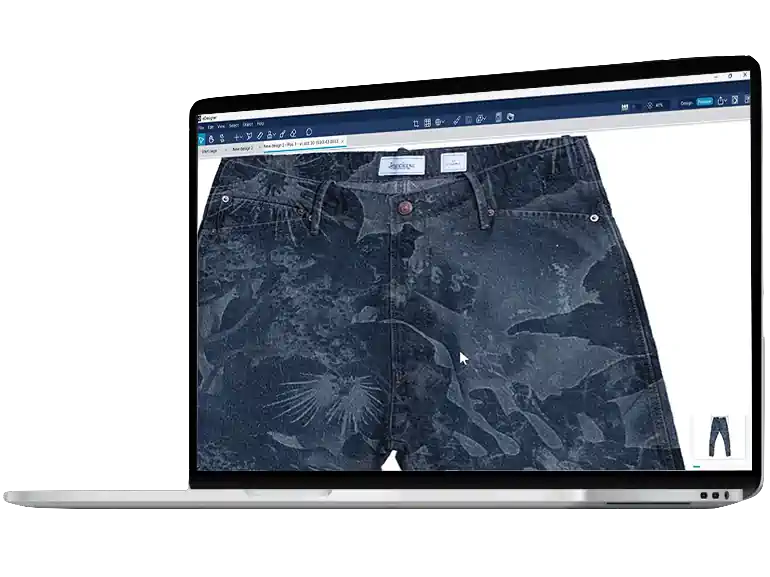

Cutting-Edge 3D Sampling: Transforming Fashion's Future with Efficiency and Resilience

New technological innovations reduce the need for physical fabric sampling, creating convincing and accurate 3D samples that surpass mere artistic 3D models. These samples are photorealistically identical to the fabrics that arrive in bulk production. Utilizing innovative solutions will propel us more rapidly towards the efficient and sustainable future of the fashion industry. Brands require a backup plan due to potential supply chain disruptions, remote working, and an increase in natural disasters, pandemics, and political unrest. 3D sampling provides that safety net without compromising quality and accuracy.

Scientific Data

Green Win Zone US offers unparalleled access to precise, scientific data on fabric reactions to advanced technologies like laser treatment. Our in-depth analysis enables designers to understand how different fabrics respond to laser technology, ensuring optimal results in garment creation. This data-driven approach empowers designers to make informed decisions, enhancing both the quality and innovation of their designs.

Perfect match between fabric and finish

Make the best fabric choice simple by having a single value as a reference produced at the end of each analysis.

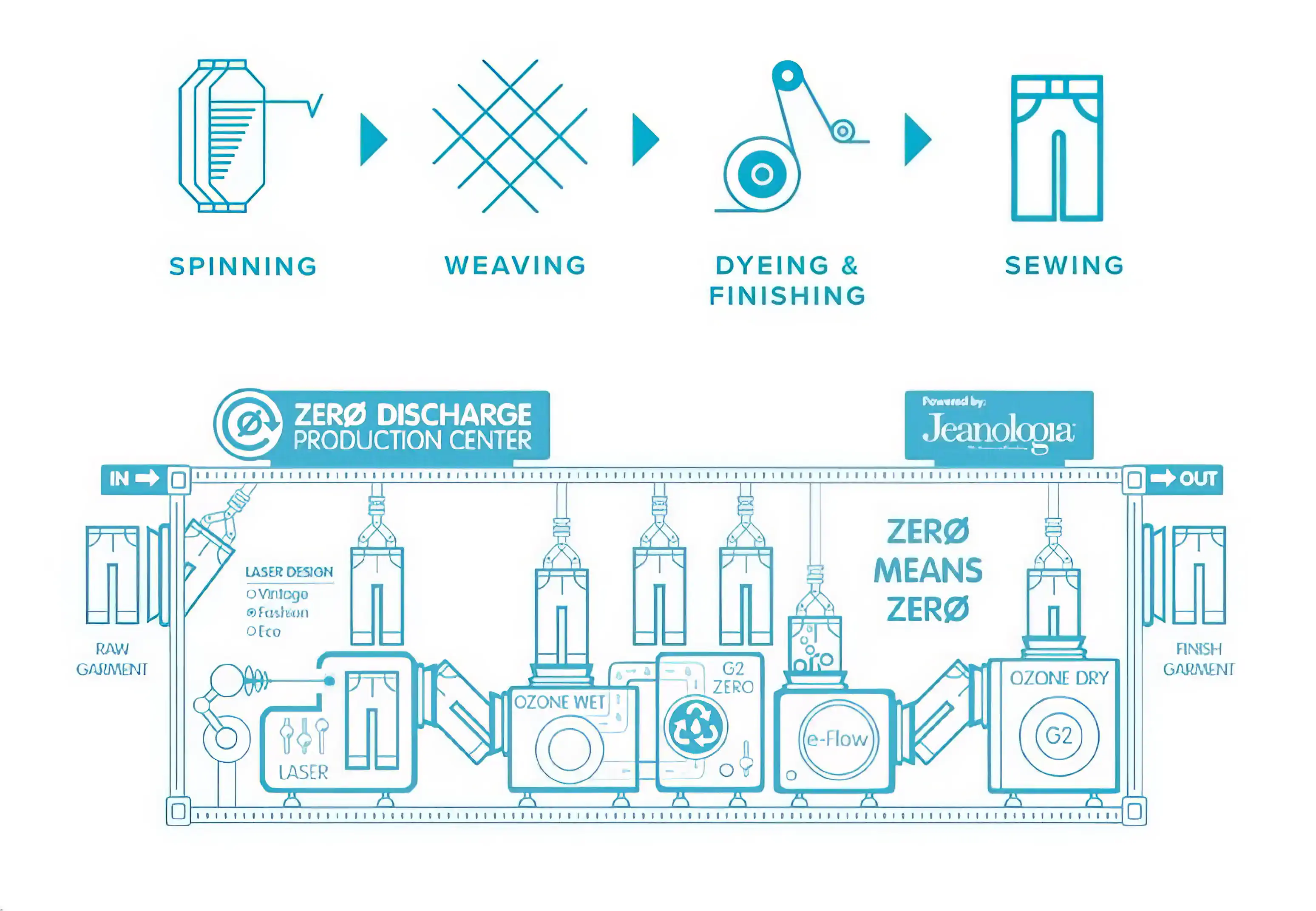

Green Denim Manufacturing Excellence

Our denim production combines cutting-edge technology and sustainable practices. We use advanced Jeanologia machinery to save water, energy, and chemicals, while maintaining a waste management system. We offer organic and recycled cotton from Africa and BCI fabric from Egypt. With a short supply chain and low environmental impact, we deliver toll-free to the EU and under certain conditions to the US in just 3-4 weeks. Our dedicated team keeps pace with fashion trends, offering creative sampling, and a yearly production capacity of 1,000,000 units with 900 employees.

Laundry 5. Zero a new production model based on digitalization and sustainability that reduces time and simplifies processes, reinventing the way of producing jeans. It is the first eco-efficient plant that guarantees a saving of up 85% in water and guarantees zero discharge and zero pollution. The implementation of Jeanologia technologies: Laser, G2 ozone, e-Flow, SmartBox, and H2Zero, make it possible to eliminate polluting traditional processes such as potassium permanganate, pumice stone, substances of concern, and discharge from the textile finishing industry, as well as the harmful manual processes of scraping and grinding. We study your needs and together we build a tailor-made project, having a sustainable production capacity of 5,000 to 25,000 garments per day.

We utilize FedEx Express for sending samples via air, ensuring swift delivery to your doorstep.

Our commitment to efficiency means that your samples are delivered promptly, courtesy of FedEx Express.

We tailor our shipping methods to meet your specific needs, offering air or freight options for bulk orders.

Our commitment to efficiency means that your orders are delivered promptly.